Microtunneling Case Study | Pate Garver and Hobas Pipe

Breaking New Ground: A Look Back at One of Hobas Pipe’s First Microtunneling Project: The history of microtunneling in the United States is one of innovation and perseverance. Among the pioneers of this groundbreaking technology is BRH Garver, a company that has been at the forefront of trenchless technology for decades. During the recent Texas Water show, I had the privilege of sitting down with Alan Pate, president of Pate Garver, successor to BRH Garver which had been purchased by a Private Equity Firm, to discuss his company’s early experiences with Hobas Pipe and its role in advancing microtunneling in the U.S.

The Early Days of Fiberglass Pipe in Microtunneling

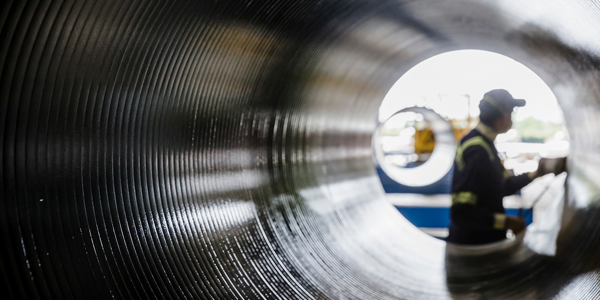

When Hobas Pipe first began manufacturing fiberglass-reinforced pipe in the U.S., microtunneling was still in its infancy. Engineers and contractors were looking for materials that could withstand the challenges of trenchless installation while offering longevity and structural reliability. Pate Garver quickly recognized the potential of Hobas Pipe’s fiberglass-reinforced polymer mortar (FRPM) pipe for these demanding applications.

Alan Pate recalled one of the earliest microtunneling projects BRH Garver Construction undertook using Hobas Pipe. The project, which took place in 1988, was actually an early microtunneling project in the U.S. It required two tunneling machines and presented significant technical challenges due to soil conditions, groundwater infiltration, and stringent alignment requirements. At the time, most contractors were accustomed to using traditional materials like concrete and steel, but Pate Garver saw an opportunity to leverage the benefits of fiberglass pipe. “It was difficult to use concrete pipe because it would break,” Alan Pate explained. “Then we found Hobas Pipe.”

Overcoming Challenges with Innovation

One of the primary advantages of Hobas Pipe in microtunneling is its smooth exterior, which reduces jacking forces during installation. This was a game-changer for Pate Garver, allowing them to push longer drives with greater precision. Additionally, the corrosion-resistant nature of the pipe meant that it could be installed in aggressive environments without the need for protective coatings or linings. Another critical advantage is that Hobas Pipe does not absorb water, making it even more reliable in difficult conditions.

Alan Pate emphasized how the project helped shape industry perceptions of fiberglass pipe. “The ability to maintain structural integrity while withstanding the stresses of installation proved that Hobas Pipe was a reliable solution. Hobas Quality Control is very reliable and the pipe behaves predictably. We would tunnel only with Hobas.”

The Lasting Impact on the Industry

The success of this early microtunneling project set a precedent for future installations. It demonstrated that fiberglass pipe could not only meet but exceed the expectations of the industry. As a result, Pate Garver and other contractors began incorporating Hobas Pipe into a growing number of trenchless projects, paving the way for its widespread acceptance.

Today, dDecades after that first project, Hobas Pipe remains a preferred choice for microtunneling applications across the country. Its lightweight yet durable composition, resistance to corrosion, and smooth installation process have solidified its place as a leading solution in the trenchless industry. Additionally, its ability to handle high jacking loads further enhances its reputation as the go-to pipe for microtunneling.

Today’s microtunneling projects are more complex than ever, often involving larger diameters, longer drives, and stricter environmental regulations.

Reflecting on those early days, Alan Pate expressed pride in his company’s role in advancing microtunneling technology. “Looking back, it’s incredible to see how far we’ve come. Hobas Pipe played a key role in that journey, and we’re proud to have been among the first to put it to the test in real-world conditions.”

As microtunneling continues to evolve, the pioneering work of companies like Garver and the innovations brought forth by Hobas Pipe serve as a testament to the power of collaboration and forward-thinking engineering. Their contributions have helped shape the infrastructure of today—and will continue to influence the industry for generations to come.

Garver/Hobas Jacking Pipe History in the City of Houston

| Project Name | Year | Quantity |

| 18 Inch | ||

| Forest Hill | 1988 | 13,068 |

| 80th Street | 1988 | 4,170 |

| Kellogg Pump Station | 1989 | 180 |

| Berkley LS | 1989 | 9,090 |

| Eastex Oaks Village Sewer | 1990 | 1,460 |

| Studemont | 1992 | 2,905 |

| 20 Inch | ||

| Mangum Rd Contract 2 | 1994 | 80 |

| Chanute LS | 1994 | 2,439 |

| Center St. Contract 2 | 1994 | 566 |

| Will Clayton Collection Sys. | 1997 | 682 |

| 24 Inch | ||

| 80th Street | 1988 | 4,640 |

| Forest Hill | 1988 | 2,450 |

| Berkley LS | 1989 | 1,600 |

| Astrodome #4148 | 1990 | 1,060 |

| Maxey Rd | 1991 | 1,216 |

| Usener and Garden San Sewer | 1993 | 3,090 |

| Wirt Rd Paving and Drainage (Sub to Reytec) | 2017 | 3,120 |

| Force Main R/R Orem, Beechnut and Eldridge | 2021 | 3,864 |

| 30 Inch | ||

| West District Sewer Diversion | 1988 | 1,790 |

| Berkley LS | 1989 | 3,500 |

| Maxey Rd | 1991 | 2,312 |

| Galleria Area Diversion Sewer | 1992 | 320 |

| Ayrshire Neighborhood Overflow | 1993 | 480 |

| Mangum Rd Contract 2 | 1994 | 2,248 |

| Center St. Contract 2 | 1994 | 1,616 |

| Center St. Contract 1 | 1994 | 810 |

| Songwood Area Relief | 1995 | 2,488 |

| Vickery Rd 54″ Waterline (Sub to Harper) | 2017 | 3,015 |

| 36 Inch | ||

| Maxey Rd | 1991 | 384 |

| Lockwood Pump Station | 1992 | 395 |

| Bell St Sanitary Sewer Relief | 1992 | 5,156 |

| Woodway Relief Sewer System | 1993 | 270 |

| Mangum Rd Contract 2 | 1994 | 5,600 |

| Harbor Relief Sewer | 1996 | 3,070 |

| Upper and Lower Lockwood | 1996 | 4,300 |

| Sleepy Hollow LS | 2020 | 4,276 |

| 42 Inch | ||

| Forest Hill | 1988 | 3,275 |

| Berkley LS | 1989 | 1,600 |

| Almeda Sims #1 | 1990 | 380 |

| Woodway Relief Sewer System | 1993 | 1,000 |

| Center St Contract 1 | 1994 | 3,590 |

| Brookwoods and TC Jester | 1996 | 4,300 |

| Petit and Foyce Relief Sewer | 1997 | 2,470 |

| North Eldridge LS | 1999 | 2,344 |

| Sims Bayou Sewer Relocation | 2009 | 1,647 |

| 48 Inch | ||

| West District Diversion V | 1992 | 1,280 |

| Northwest Sludge Transfer Tunnel | 1993 | 70 |

| Woodway Relief Sewer System | 1993 | 4,000 |

| Ayrshire Neighborhood Overflow | 1993 | 80 |

| Center St Contract 1 | 1994 | 1,340 |

| Belmont LS | 1995 | 2,225 |

| Belmont Area Pump Station | 1997 | 595 |

| Holmes Rd Sanitary Sewer | 2017 | 4,372 |

| Fountain View LS | 2020 | 3,700 |

| 54 Inch | ||

| LS Renewal Renwick | 2016 | 14,145 |

| North Corridor PKG 1A | 2018 | 3,940 |

| Fountain View LS | 2020 | 102 |

| 60 Inch | ||

| Eastbank Relief Interceptor | 1997 | 3,940 |

| Sims Bayou Sewer Relocation | 2009 | 207 |

| Chelford City PKG 1A | 2019 | 4,554 |

| Chelford City PKG 1B | 2021 | 4,551 |

| 85 Inch | ||

| North Corridor PKG 1A | 2018 | 600 |

| 90 Inch | ||

| Sims Bayou Sewer Relocation | 2009 | 468 |

| TOTAL | 168,485 |