In March 1992 Archer, Daniels, Midland Co. (ADM) diverted their effluent flow into their new Hobas line and quickly learned that only two of the three 100 HP pumps were needed.

Shutting down one 100 HP pump saves 650,000 KWH per year; an annual electricity savings of $32,500 at five cents per KWH.

Very significant funds.

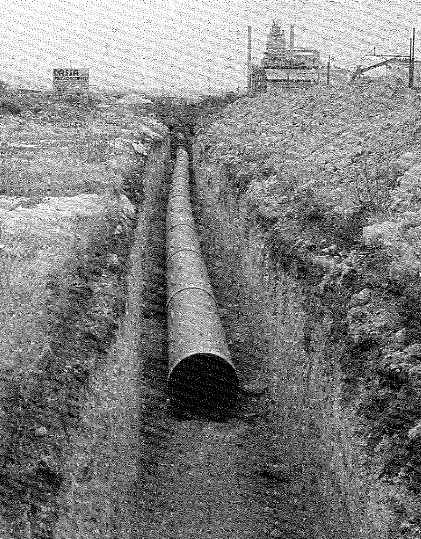

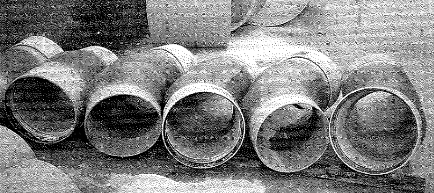

The 24″ diameter, PN 100 Hobas fiberglass pipes replace an existing cast iron force main at the Illinois food processing plant. The over three mile long line was supplied in 20 ft. sections joined in the field with the gasket-sealed, push together Hobas FWC couplings. Fiberglass fittings provided included elbows, flanges, nozzles and reducers.

Durability Was Paramount

The effluent analysis ranged from ph 3 to ph 8 at an operating temperature of up to 100°F. with occasional upsets of short duration up to 150°F.

Because of this demanding service, ADM and project engineer, Ed Milanski of Bainbridge, Gee and Milanski of Decatur, needed a pipe with excellent corrosion resistance, leak-free joints and a long service life. ADM turned to fiberglass because of past dissatisfaction with the durability of thermoplastic pipes and cement lined pipes in similar services.

Hobas USA was selected as the supplier because of their high quality pipe, superior technical assistance and a competitive price.

Successful Installation

Installer, Bodine Sewer of Decatur found the lightweight Hobas pipes easy to handle and fast to assemble. The flexible joints, which permit two degrees rotation allowed easy field grade and alignment adjustments.

The bedding and embedment of crushed rock made burial simple and resulted in an essentially round pipe after backfilling. Bodine Sewer also enjoyed the easy field fabrication possible with Hobas pipes. Because of the smooth, constant O.D. produced by the centrifugal casting manufacturing process, Hobas pipes may be cut anywhere along their length and joined using the FWC coupling without any preparation other than chamfering the cut edge.

Also appreciated was Hobas USA’s quick service (less than one week) on special order fittings necessitated by some field changes.

Leak-Free Test Shows Toughness

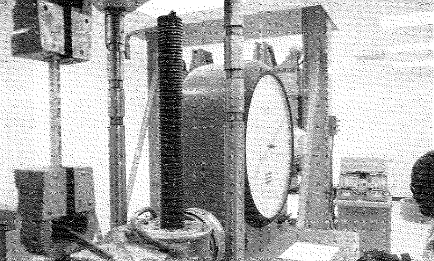

Despite the importance of the many cost saving benefits Bodine Sewer experienced during the installation, their greatest reward may have been the line hydrotest performance. At some risk, only low pressure air testing was done as the installation progressed.

After completion, a two hour, 125 psi hydrotest was conducted without loss on the first attempt!

Certainly this is a testament to the Hobas pipe consistency and toughness, the quality and design of the FWC coupling joints and the expert installation of Bodine Sewer.

Nearly “Free” Pipe

ADM will derived numerous benefits from their Hobas effluent line for many years to come. The leak-free joints protected the environment and avoid penalties imposed from spills. The inherent corrosion resistance provided the durability required for a long, trouble-free service life. And perhaps most important, the present value of the pumping electricity savings over 50 years is over $322,000 (assuming a 10% money cost and no inflation). Considering all this, the Hobas pipes are nearly “free”.

First Hobas Pipe Installation

The first installation of Hobas fiberglass pipes was in Victoria, Texas on the Ben Wilson Relief Sewer II Project. As the job name implied, the nearly 12,000 ft. of new lines provided flow relief. The addition includes 30″ and 36 interceptors and a 20″ force main, all supplied in 20 ft. sections. The Hobas pipes, assembled with fiberglass FWC couplings, connect to A-lock gasketed manholes.

Tight Specification

Project designer, Robert Wycoff of Wycoff Engineering in Victoria faced several critical performance issues regarding the pipe specifications including citywide corrosion problems in the existing system, the expansive clay native soils and tight controls on discharge flows. These considerations demanded a corrosion resistant, high strength pipe with tight joints.

Additionally, the City was seeking a high quality alternative to provide competition for ductile iron on the force main. For all these reasons, only Hobas, ductile iron with coal tar epoxy lining and extra strength vitrified clay (interceptors only) pipes were allowed. Also, the interceptor leakage limit was set at 50 in-gal.

Overwhelming Benefits of Hobas Pipes

John Byrum, Director of the City Water & Wastewater Dept. awarded the contract to low bidder, SG&R Construction of Huntsville, Texas based on Hobas pipes for several reasons including a $62,000 installed deduct versus the other materials. Additionally, Mr. Byrum favored Hobas pipes because of their inherent corrosion resistance, which is not susceptible to field damage.

The ease of field cutting and modifications, as well as lower maintenance and operation costs also pleased the City.

Satisfied Customer

With the installation over 50% complete, SG & R found Hobas pipes easy to assemble and bury with a best day of about 300 ft. The compacted sand pipe surround and the Hobas pipe stiffness have combined to limit most deflections to less than 1% with a maximum of less than 2% at cover depths up to 18 ft. With this successful experience, the City looks forward to future Hobas installations.

Hobas Extends Pipe Life in Hot Service

Hobas USA fiberglass pipes are extending the service life of the exhaust and drainage system serving the Dow Chemical magnesium production units in Freeport, Texas. The special 18″ diameter pipes constructed with Dow Derakane 470 resin and a special sand filled liner, are ex- posed to very high temperatures. The two 400 foot long headers serve 54 reactors. The short pipe sections are supported on hangers and are joined by teflon lined rubber wraps banded in place.

Demanding Service

The normal service condition is chlorine and hydrochloric exhaust gases and quenching spray water drainage, both entering the Hobas pipes at up to 90° C. (194°F.). The infrequent upset condition of the exhaust gases at 400° C. (752°F.) to 500°C.

(932°F.), occurs when the quenching water spray is temporarily not operating. In this circumstance, the high temperature is rapidly dissipated through quick mixing with nearby adjacent “cooler” flows.

Extended Life Reduces Replacement Costs

Dow originally used asbestos cement (A/C) pipes in this application. When it was necessary to remove the A/C pipes, filament wound fiberglass (FW) pipes were substituted.

The FW pipe average service life was only a few months, because of rapid deterioration after one upset exposure.

The special Hobas pipes, however, withstood up to 3 upset exposures before replacement was necessary.

Hobas pipes not subjected to the upset conditions are still serviceable after 3 years.

An additional benefit for Dow is the much lower flame spread of the Hobas vs. FW pipes. This feature isolates the damage caused by the upset condition to fewer pipes, further reducing replacement costs. The Hobas pipe success in the magnesium production units is leading to additional applications in Dow’s operations.

Hobas Pipes Approved by L.A. “Green Book”

Definition/Scope of the “Green Book”

The Los Angeles “Green Book” (as it is often referred to) is the standard specifications for Public Works Construction in southern California. The “Green Book”, written and promulgated by the Joint Cooperative Committee of the Southern California Chapter American Public Works Association and the Southern California Districts Associated General Contractors of California, covers contracts, inspection, responsibilities, materials and methods.

Representation on the “Green Book” committees includes personnel from the City of Los Angles, Los Angeles “Green Book” County Sanitation Districts of Los Angeles County, City of San Diego, other major agencies and leading consulting engineers.

Approval of Hobas Pipe Specification:

After three years of testing, review and evaluation by the “Green Book” committees, a Hobas pipe specification for rehabilitation applications was approved in November, 1991. It will be published in the 1992 Addendum to the 1991 edition of the “Green Book”. Future activities will include work to expand specifications for additional applications.

Approval of Hobas pipe by this widely recognized specification group, adds additional weight to the success achieved by Hobas nationwide.